Privacy Policies | Disclaimer Contact to : sales-tre@thereccorp.com

The THEREC and the TRC are trademark owned by THEREC CORPORATION LTD. Used with permissions. Trademark & Other intelectual property right Notices ©2013-2017

THEREC Corp. © All Rights Reserved. © 2021 THEREC Corporation Limited.

Tel : +662 893 9003-4, +662 893 9177, +662 893 9179, +662 895 0929, Fax : +662 893 9005

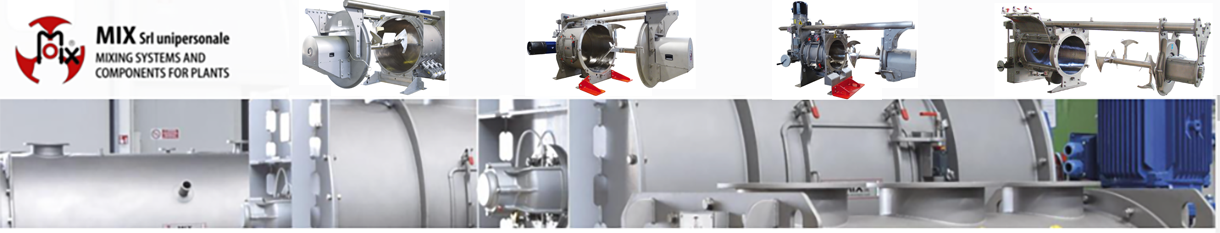

Industrial grade powder mixer | Horizontal mixer | Chemical powder mixer |

|